Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

Properties

- Typical Properties

Value Units Test Method / Conditions Density 8.4 - 10.0 lb/gal - Open Time 20.0 s - Green Strength (min. 50 psi) 15.0 s - Application Temperature 130 - 140 °C -

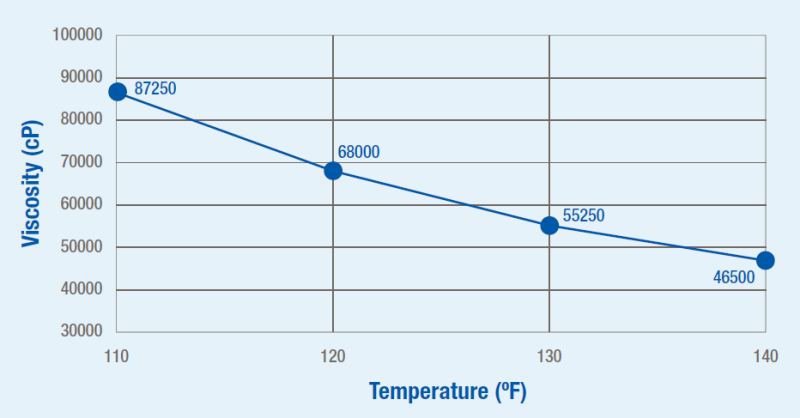

Technical Details & Test Data

- Viscosity Curve

Safety & Health

- Environmental Recommendation

This product cannot be disposed directly in the sewers. Even though the product has a more environmental-friendly formulation, there are many chemicals in a PVAc dispersion that cannot be considered to have a neutral impact in the environment.

- Safety Information

Use only in equipment intended for reactive hot melts. Use with local exhaust ventilation to remove vapors anywhere heated product is exposed to air including adhesive un-loaders, pre-melters, and application areas. Local exhaust ventilation may be required to maintain exposures at safe levels.

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 9 Months

- Storage Condition

To ensure maximum stability, product should be stored in the original closed container in a clean and dry interior location capable of maintaining a constant temperature between 50°F and 90°F.