Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

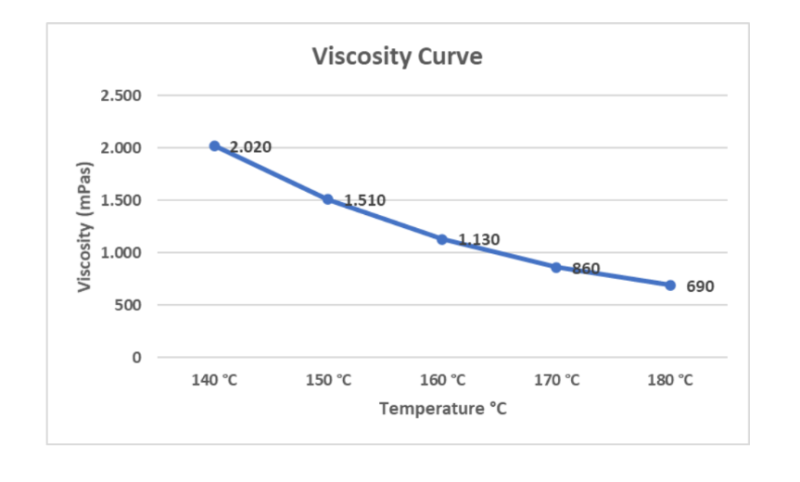

- Viscosity Graph

Features & Benefits

- Ready-to-Use Product Features

- Product Characteristics

- High hot tack.

- Resistance ofthe glue to standard storage and transportation temperatures.

- Suitable for medium and high speed machine applications.

- Designed to perform well even under ambient temperature conditions.

- High performance on boxes and substrates with medium memory effect.

Applications & Uses

- Markets

- Applications

- Application Area

- Typical Applications

BAMFutura 45 is suitable for bonding standard boxes (such as boxes for the EOL End of Line market), and has excellent performance at ambient temperatures and high machine speeds. It is an adhesive with high thermal stability, which allows for lower maintenance costs and less machine downtime. The BAMFutura 45 has an affinity with many types of paper and corrugated, but as the variety of substrates in the industry is very high, prior adhesion/bonding tests are recommended to ensure that the adhesive meets the specific requirements.

- Application Instructions

BAMFutura 45 should be applied between 150°C and 180°C. This temperature can be adjusted according to a few factors such as the amount applied, the substrates involved, the ambient temperature, and machine conditions such as compression time, among others.

Properties

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Typical Packaging

H.B. Fuller hotmelt adhesives are usually packaged in bags or boxes.

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

Keep the product in its tightly closed packaging, protected from sun, dust, humidity and high temperatures. Keep in a clean, dry place at temperatures between 5°C and 30°C.