Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Characteristics

The ADECOL® CQ-7039/5 adhesive has excellent thermal stability, excellent oxidation resistance due to high surface tack, has excellent adhesion on several substrate types, high relation adhesion/cohesion, as well as high flexibility and elasticity.

Applications & Uses

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Typical Applications

- This adhesive has been specially developed for mounting and closing security envelopes, plastic envelopes (PE, PP and PS), where high temperature resistance is required, used in high performance equipment with nozzle application systems, slot, spiral or spray.

- For best adhesion results on substrates such as PE, PP, PS ABS, PET/PBT blends, concrete, wood, metal and sheet metal, we suggest the use of a chlorinated polyolefin primer and solvents.

- Application Instructions

Surfaces should be free dust, grease or oil, the application temperature range should be checked at each specific step according to the following factors: Characteristics of substrates, equipment, speed, quantity adhesive and ambient temperature.

- Suitable Substrates

Security envelopes, plastic envelopes (PE, PP and PS), PET/PBT blends, concrete, wood, metal and sheet metal.

Properties

- Physical Form

- Typical Properties

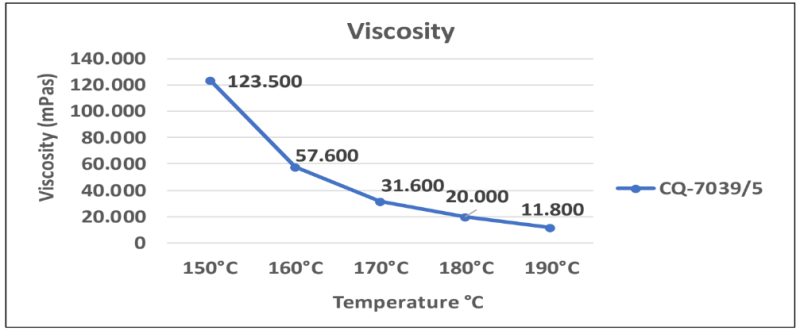

Value Units Test Method / Conditions Viscosity (sp 27/5 rpm, at 180°C) 15.000 - 23.000 mPa.s Brookfield RVT Softening Point 110.0 - 125.0 °C - Application Temperature 150.0 - 190.0 °C - Film Transparent - -

Technical Details & Test Data

- Viscosity Graph

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

In the original packaging, well closed and protected from the sun, dust, humidity and high temperatures. Clean and dry place, temperature between 5°C and 35°C is advisable.