Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Compatible Substrates & Surfaces

- Product Application Instructions

- Surfaces to be bonded should be clean and dry. Dispense a drop or drops to one surface only. Apply only enough to leave a thin film layer after compression. Press parts together and expose to UV dose when ready. An adequate bond should develop rapidly, depending on UV dose efficacy, and maximum strength is attained in 24 hours. Wipe off excess adhesive from the top of the container and recap. products, if left uncapped or exposed to sunlight, may deteriorate or cure prematurely.

Properties

- Physical Form

- Appearance

- Light straw liquid

- Cured Mechanical Properties

Value Units Test Method / Conditions Hardness 86 - Shore A, ASTM D2240 Hardness 57 - Shore D, ASTM D2240 Elongation to Break 400 % ASTM D638 - Cured Properties

Value Units Test Method / Conditions Flash Point min. 95 °C - Set Time (at 395nm) max. 4 sec - Wavelength 50 mW/cm² - Full Cure Time 24 hrs - Storage Condition (in darkness) 8 - 21 °C - Optimum Wavelength 300 - 420 nm - Cured Appearance Colorless solid - - - Specifications

Value Units Test Method / Conditions Specific Gravity 1.06 - - - Rheological Properties

Value Units Test Method / Conditions Viscosity (at 20 - 25°C) 3000 - 5000 cPs - - Curing Properties

- Photoinitiation initiates the curing process. Handling strength is reached in a short time, and will vary based on UV dose efficacy, environmental conditions, bond line gap, and other factors. Product will continue to cure for at least 24 hours before full strength and solvent resistance is developed.

Technical Details & Test Data

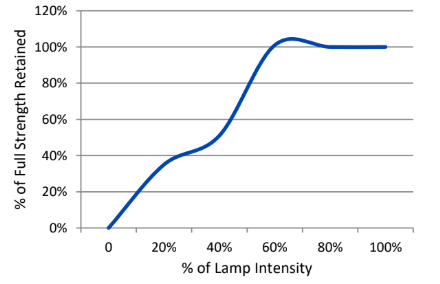

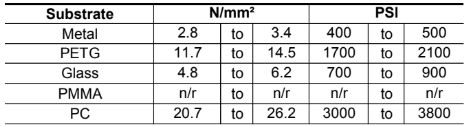

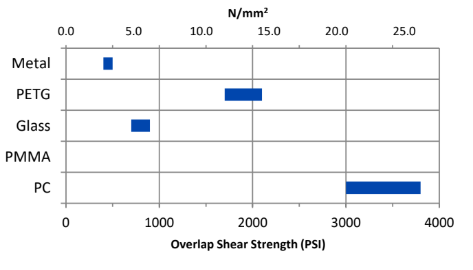

- Graphical Information

Percent Strength Retained at Given Dosage

Performance of Cured Adhesive

Performance Range, by Substrate

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 9 months (Cured)

- Storage Information

- Products should be stored unopened in a cool, dry place out of direct sunlight. Products should be kept at room temperature away from direct light. Protect from extreme heat or cold, do not refrigerate.