Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Product Characteristics

- After curing a high cold, heat and humidity resistance will be achieved

- The cross-linked product has high mechanical properties

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- Typical Applications

Suitable for coating of PVC window profiles with PVC foils.

- Application Instructions

- Application temperature: 120°C - 140°C

- Open time: approx. 20 - 40 seconds, depending on temperature, amount and substrate.

- Good results will be achieved if the following conditions are observed:

- Room and material temperature: 18°C - 20°C

- Moisture content of wood: 8 - 10%

- Relative humidity: 40 - 60%

- Because of the low application temperature, the thermal stress of heat sensitive materials is low. The physical and chemical curing is affected by the specific temperature of the PVC-profiles. The surfaces of the substrates must be clean, dry and free from oil and grease.

- The temperature of the substrates must not be below +18°C during coating as lower temperatures deteriorate adhesion of glue and shorten open time. PVC and Alu-profiles should be heated to about 45°C - 55°C. After physical curing bonded parts are quickly ready for further processing. PVC profiles must be pre-treated with primer. The adhesive can be applied by nozzle-, roller- and spray equipment.

- As a matter of principle, care has to be taken that melting and application equipment is protected against incoming moisture. This can be reached by applying dry nitrogen or dry air. Final strength is achieved after 1 - 3 days depending on availability of moisture and temperature.

- Please care for exhaust of vapors occurring during application. Due to the variety and diversity of the market materials, it is necessary to do own tests for the use of this product.

- Swift®prime 4956 FL can be used as primer for Swift®lock 4780

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Viscosity (Brookfield Thermosel, Sp29, at 120°C) approx. 38,000 mPa.s Density approx. 1.10 g/cm³ - Open Time 20 - 40 s - Softening Point approx. 75 °C Application Temperature 120 - 140 °C -

Technical Details & Test Data

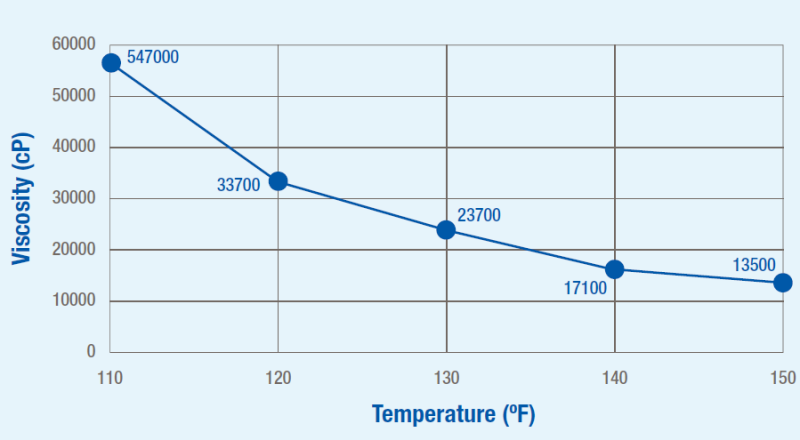

- Viscosity Curve

Safety & Health

- Safety Information

Use only in equipment intended for reactive hot melts. Use with local exhaust ventilation to remove vapors anywhere heated product is exposed to air including adhesive un-loaders, premelters, and application areas. Local exhaust ventilation may be required to maintain exposures at safe levels.

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 9 Months

- Storage Condition

In original sealed packaging, clean and dry conditions above -25°C and below +35°C. Sensitive to humidity.