Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- For optimum results parts should be clean and free from any contamination on the bonding surface. If parts do not mate flush together use a higher viscosity product to compensate for the gap. Factors Affecting Cure Speed Include: GAP: Thin bond line results in faster cure speed. Larger gaps will lengthen cure speed. HUMIDITY: Cure and fixture times can be influenced by the humidity conditions at the time of assembly. The higher the RH the faster cure and fixture times will be. Fixture time data based on our testing is conducted at 50% relative humidity.

Properties

- Appearance

- Clear viscous liquid

- Cured Properties

Value Units Test Method / Conditions Full Cure Time 0 - - Cure Appearance 0 - - Service Temperature 0 - - - Resistance

Value Units Test Method / Conditions Alcohol* 0 - - Ester (Aromatic)* 0 - - Ketone (Aromatic)* 0 - - Aliphatic Hydrocarbon (Alkanes)* 0 - - Aromatic Hydrocarbons* 0 - - Halogenated Hydrocarbons* 0 - - Weak Aqueous* 0 - - Weak Aqueous Base* 0 - - - Uncured Properties

Value Units Test Method / Conditions Flash Point 0 - - Set Time (Steel) max. 20 sec - Set Time (ABS) max. 15 sec - - Specifications

Value Units Test Method / Conditions Specific Gravity 1.09 - - - Rheological Properties

Value Units Test Method / Conditions Viscosity 2400 cPs - - Note

- * for solvent

Technical Details & Test Data

- Cured Properties

Time Until Full Cure (% of RT strength)

Performance Range by Substrate (N/mm²)

Performance of Cured Adhesive

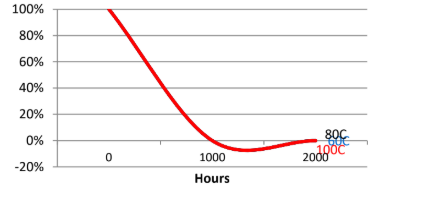

Heat Aging (aged at temp indicated and tested at 22°C)

Hot Strength (%RT strength, tested at temperature)

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 0

- Storage Information

- Store product in unopened containers, out of direct sunlight, in a dry location. Material should be stored at or below 22°C. For extended shelf life unopened containers of the product may be refrigerated.