Enhanced TDS

Identification & Functionality

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- Application Information

Applications

Fields of Application

Automotive Construction Industrial assembly

Transportation Processing

Suitable Substrates

Various galvanized steels

Various aluminum alloys

Various steel alloys

Duroplastics Thermoplastics (except PE, PP, PTFE)

Various composite materials (e.g. CFRP, GFRP)

Glass Mineralic materials

Wood Coated surfaces Consistency Non-sagging Pasty

Surface Requirements

Clean Free of grease Surface Cleaning

Körasolv GL Körasolv PU Körasolv WL Adhesion Promoter (absorbing surface) Körabond HG 74 E

Adhesion Promoter (non absorbing surface) Körabond HG 83

Application Method Using side-by-side cartridge with static mixer

via two part mixing and metering systemsProduct Overpaintability Wet-in-wet (depending on paint)

Product is free of Solvents Cleaning

Cleaner for Tools

Körasolv GL Körasolv PU Hints

Resistance against UV Radiation Not suitable for glass bonding with

permanent UV radiation to the bonding area.

Please ask your local sales office for

products suitable for such applicationsStress Cracking Preliminary tests must be carried out on

plastics with a tendency to stress cracking.

(PMMA, ABS, PC or PS)Compatibility with Polystyrene Foams Not suitable for bonding polystyrene foams.

Please ask your local sales office for

products suitable for such applications.- Preparation

For some substrates the use of mechanical pretreatment and/or cleaner or primer is necessary to achieve good adhesion.

- Processing

Low temperatures can cause a temporary increase in viscosity resulting in reduced extrusion and slower curing rates.

- Cleaning Instructions

Clean tools immediately after use. Once cured, the material can only be removed mechanically. Appropriate cleaners are listed in the product properties.

- Dimensioning

The required thickness of the adhesive layer depends on the expected maximum strength and joint movement. We recommend a minimum layer thickness of 2 mm.

Properties

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Glass Transition Temperature -64.0 °C DIN EN ISO 6721-1 - Cured Properties

Value Units Test Method / Conditions Pot Life (with Köracur 310 N) 20.0 min - Pot Life (with Köracur 310 L) 40.0 min - Pot Life (with Köracur 310 SL) 60.0 min - Change in Volume -3.0 % DIN EN ISO 10563 Hardness (after 14d) 36.0 - DIN ISO 7619-1, Shore A Tensile Strength 2.6 MPa DIN EN ISO 527 Elongation at Break 450.0 % DIN EN ISO 527 Tear Strength 18.0 N/mm ASTM D624 - Processing Parameters

Value Units Test Method / Conditions Mixing Ratio (Part A:Part B, by volume) 10:1 - - Processing Temperature 5 - 35 °C Recommended Minimum Layer Thickness 2.0 mm - - Recommended Operating Conditions

Value Units Test Method / Conditions Service Temperature - 60 - 90 °C - Short-Term Temperature Resistance (60 min) 120.0 °C - - Physical Properties

Part A Körapop 225

Physical Properties

Density 1.4 g/cm3 DIN EN 542 Solid-content by weight 100% Processing Guidelines and Parameters

Storage Temperature 5 °C to 25 °C Part B Köracur 310 N

Physical Properties

Density 1.49 g/cm3 DIN EN 542 Processing Guidelines and Parameters

Storage Temperature 15 °C to 25 °C Part B Köracur 310 L

Physical Properties

Density 1.49 g/cm3 DIN EN 542 Processing Guidelines and Parameters

Storage Temperature 15 °C to 25 °C Part B Köracur 310 SL

Physical Properties

Density 1.49 g/cm3 DIN EN 542 Processing Guidelines and Parameters

Storage Temperature 15 °C to 25 °C

Technical Details & Test Data

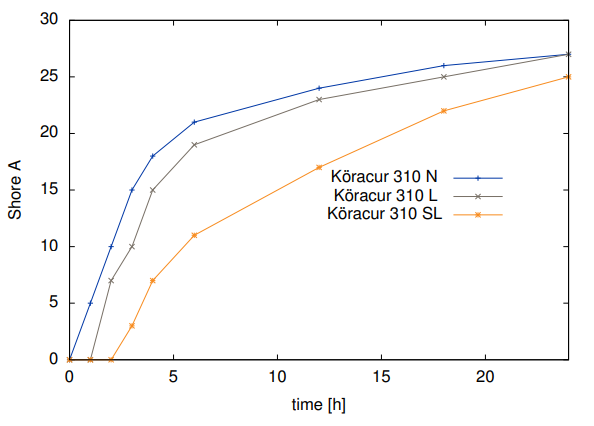

- Curing of Körapop 225-2K

Curing of Körapop 225-2K with different boosters, build up of Shore A

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Storage Conditions

Körapop 225-2K should be used within the shelf life specified on the packaging. The storage stability only applies to material stored under appropriate conditions (original unopened containers, recommended storage temperature).