Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Attributes

100 % Solids, Low VOCs, Isocyanate Free

- Safe for acrylic mirror - Gunther Premier® Plus is recommended for use with acrylic mirror meeting federal specifications and will withstand exposure to UV light. • NO ODOR Great for remodel and enclosed applications where venting is an issue and odor is a concern.

- Easy Working Consistency Year-round - Gunther Premier® Plus is gunnable from 60°F to 100°F, Premier® Plus can build out to 2: or compress down to 1/32”. For best adhesion surfaces should be dry, clean and above 60°F.

- Remains Flexible - Gunther Premier® Plus holds firmly, yet absorbs movement due to expansion and contraction. Will not become brittle with age, ever. Great for high traffic areas such as gymnasiums, hallways, dance studios, etc. Water resistant for use in showers and outdoor applications.

- Convenient Drying - Gunther Premier® Plus cures to 20% of maximum strength in 24 hours. Cures to 100% strength in 7 days at normal room temperatures and humidities.

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Installation Instructions

- The surface must be clean, dry and free from dust, dirt, greasy film, loose or powdery paint or primer. Primed surfaces should be checked thoroughly. It is recommended to sand through to the base sufrace where mastic will be applied. Clean and then seal with Gunther Prime-N-Seal™. Let thoroughly dry. Gunther Prime-N-Seal™ will add strength to the wall and prevent caustic lime deposits from attacking the mirror backing. Wall and mirror surfaces must be above 60°F. Do not apply on wallpaper, paint, Category I vinyl safety backing or treated woods.

- FOR BEST RESULTS: Apply Gunther Premier® Plus in vertical beads on the substrate, the length of the mirror, 5-6” apart. Allow 3” from the mirror edge to begin or end a bead. You can also apply Gunther Premier® Plus in patties 4-5” in diameter for every square foot of mirror surface.

- Use a mechanical support system to support mirror during and after Installation.

- Gunther Premier® Plus can build out to 2“ for large mirrrors or uneven wall jobs, or can be compressed to 1/32” for mirror overlays or installations requiring close tolerances. MIRROR OVERLAYS: Working with mirror strips can be difficult. For overlays, use Gunther Ultra/Bond® or Premier® Plus to achieve a fast set and strength along with double-faced tape. Ultra/Bond® has the capability to compress to 1/32”, Premier® Plus to 1/16”, providing a professional installation. Double-faced tape is used only for initial adhesion to support the mirror. The mastic is for long term adhesion and strength. Mastic beads of 1/4” to 3/8” thick by 6” long, leaving a 3” gap between where the bead starts will improve curing time. NOTE: Check with mirror manufacturer on recommended double-faced tape.

- Easy to apply at temperatures ranging from 60°F to 100°F without auxillary heating equipment.

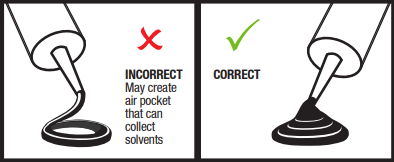

Do not apply mastics in a circle where an air pocket could collect solvents and possibly extract material that could be damaging to the mirror. The best way to apply Premier® Plus from a cartridge is to start from the center and let the mastic naturally expand out as it’s being gunned. Mechanical support systems are recommended for all mirror applications. This includes the use of mechanical fasteners at the top and bottom of the mirror.

- Cure Rate

Rate Of Curing For Gunther Premier® Plus

Time Cured Approximate Percent of

Maximum Strength

24 hours 20% 2 days 50% 7 days 100% Curing time will depend on temperature, humidity and the amount of air to reach Premier® Plus mastic.

- Mounting Time

Mirrors can be mounted up to 20 minutes after application of Gunther Premier® Plus.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Availability

- 20 fl oz sausage

- 300 ml cartridge

Storage & Handling

- Shelf Life

- 1 Year

- Storage Conditions

Shelf life is one year in original unopened containers when stored between 40°F - 80°F.