Enhanced TDS

Identification & Functionality

Features & Benefits

- Ready-to-Use Product Features

- Key Attributes

- One component material for easy handling

- Safe and easy to use

- Adheres to a variety of substrates

- Suitable for easy application via brush, roll, or spray

- Provides added layer of protection in thermal events

- V0 UL 94 rating

- Drying Profile

EV Protect 1000 dries quickly at ambient temperatures and can typically be handled within 2 hours of application

Factor Shorter Dry Time Longer Dry Time

Coating Thickness Thinner Thicker Air Flow More Less Temperature Hotter Colder Humidity Less More

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Application Instruction

- The surface to be coated should be clean and dry prior to application of the EV Protect 1000.

- We recommend that a minimum coating thickness of 0.020” is applied for optimum performance. Product can be brushed, rolled, or sprayed onto surfaces.

Properties

- Color (Properties)

- Flame Rating

- Physical Form

- Appearance

- White viscous liquid

- Dry Properties

Value Units Test Method / Conditions Dielectric Strength 8.9 kV/mm ASTM D149 Volume Resistivity 7.1 x 10¹¹ ρ (Ω.cm) ASTM D257 Surface Resistivity 4.7 x 10¹¹ ρ (Ω.cm) ASTM D257 Vertical Burn Test V0 & 5VA - UL 94 - Wet Properties

Value Units Test Method / Conditions Viscosity (at 2.5 rpm) 120000.0 cPs Brookfield Viscosity #6 Solids (by Weight) 60.0 % ASTM C681 Solids (by Volume) 70.0 % - Specific Gravity 1.28 - ASTM D1475

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

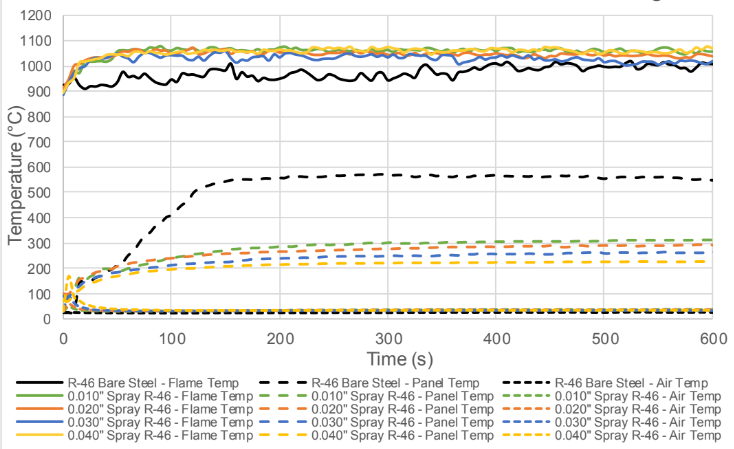

- EV Protect 1000 on Steel - 10 Minute Burn Testing

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Informations

- 5-gallon pails

- 55-gallon drum (filled to 54 gallons)

- 275-gallon plastic tote (filled to 275 gallons)

Storage & Handling

- Shelf Life

- 6 months

- Handling and Clean-Up Information

- Until EV Protect 1000 dries, overspray can be removed and equipment can be cleaned with water.

- Dried material can be removed with Methyl Ethyl Ketone.

- Storage Conditions

Store material in original unopened packaging at temperatures between 4°C to 32°C (40°F to 90°F). Shelf life is 6 months minimum when stored as recommended.