Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Application Area

- Cure Method

- General Instructions

Surfaces to be bonded should be clean and dry. Dispense a drop or drops to one surface only. Apply only enough to leave a thin film layer after compression. Press parts together and hold firmly for a few seconds. Good contact is essential. An adequate bond develops in less that one minute and maximum strength is attained in 24 hours. Wipe off excess adhesive from the top of the container and recap. products if left uncapped may deteriorate by contamination from moisture in the air. Because products cure by polymerization, whitening may appear on the surface of the container or the bonded materials. This will not affect adhesive performance.

Properties

- Physical Form

- Appearance

- Clear

- Typical Properties

Value Units Test Method / Conditions Shear Strength*** 2600 psi - Temperature Range -67 to 203 °F - Fixture Time 15 sec - - Technical Data

Value Units Test Method / Conditions Specific Gravity 1.06 - - - Cured Properties

Value Units Test Method / Conditions Service Temperature - 55 - 95 °C - Full Cure Time 24.0 h - Cure Appearance Clear - - - Uncured Properties

Value Units Test Method / Conditions Flash Point 80.0 °C - Set Time (Ethylene Propylene Diene Monomer) 5.0 s - Set Time (Steel) 15.0 s - Set Time (Acrylonitrile Butadiene Styrene) 10.0 s - - Rheological Properties

Value Units Test Method / Conditions Viscosity 2 - 6 cP Brookfield SC4-21 - Note

- *** Performance of cured adhesive on Stainless Steel

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

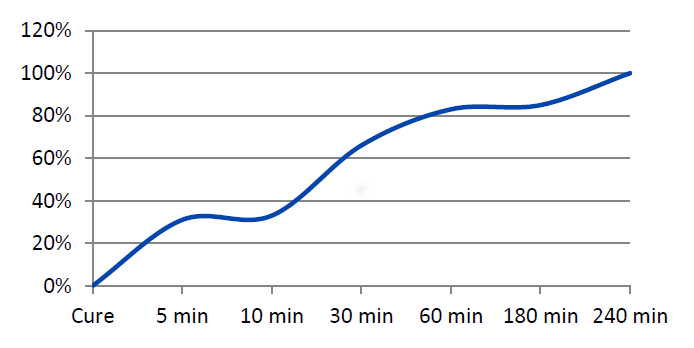

- Curing Performance

Ambient surface moisture initiates the curing process. Handling strength is reached in a short time, and will vary based on environmental conditions, bond line gap, and other factors. Product will continue to cure for at least 24 hours before full strength and solvent resistance is developed.

- Time Until Full Cure (% of RT strength)

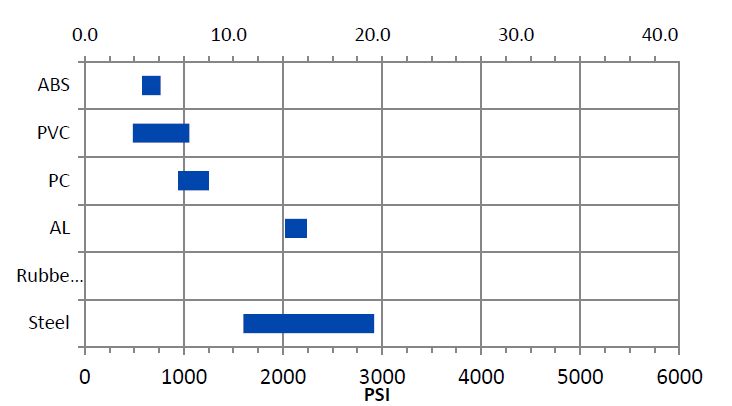

- Performance Range by Substrate (N/mm²)

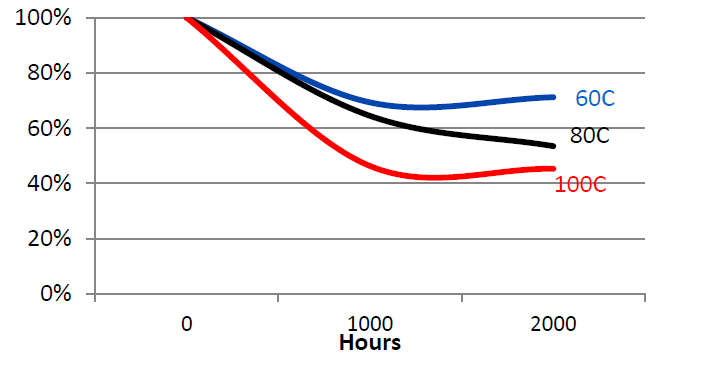

- Heat Aging (aged at temperature indicated and tested at 22°C)

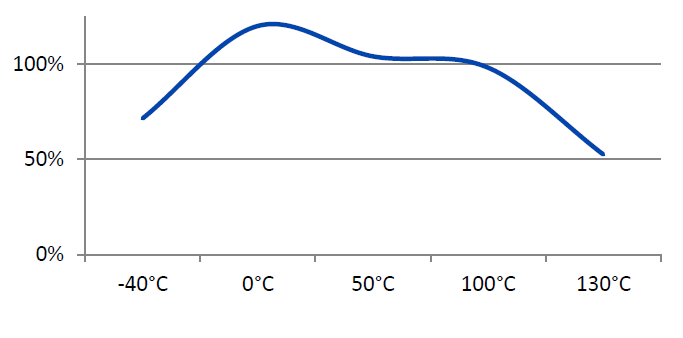

- Hot Strength (%RT strength, tested at temperature)

- Performance of Cured Adhesive

Substrate N/mm² PSI Steel 11.0 to 20.1 1600 to 2920 AL 13.9 to 15.4 2020 to 2240 PC** 6.5 to 8.6 940 to 1250 PVC** 3.3 to 7.3 485 to 1055 ABS** 4.0 to 5.3 580 to 765 *Rubber figures given are typical. Your results may vary by specific rubber type.

**Tested to ASTM 4501

***n/r = not recommended- Solvent Resistance

Solvent Example Resistance Alcohol Ethanol, Methanol

+ + + Ester (aromatic) Ethylacetate + + + Ketone (aromatic) Acetone, Benzophenone

– – – Aliphatic hydrocarbon (alkanes) Petrol, Heptanes, Hexane

+ + – Aromatic hydrocarbons Benzyl, Toluol, Xylol

+ + – Halogenated hydrocarbons Methylenchloride, Chloroform, Chlorobenzol

– – – Weak aqueous Nitrite, muriatic acid, sulphuric acid, phosphoric acid

+ + + (– – – if concentrated) Weak aqueous base sodium hydroxide solution, caustic potash

+ + + (– – – if concentrated)

Packaging & Availability

- Country Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage Conditions

Containers should be stored in a cool, dry, dark area. Storage temperature 15.5°C - 25°C (60°F - 77°F), without exposure to direct light or heat. Do not refrigerate.