Enhanced TDS

Identification & Functionality

- Backing Material Type

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Advantages

MH-200 is ready-to-use in roll form on high quality silicone release paper to assure ease of application to the sealing surface.

- Greater adhesive strength

- 100% solids to keep its volume

- Superior application time and service range

- Excellent flexibility for movement in buildings

- Withstands extreme temperatures

- Water resistant corrugated carton packaging

- Available in a variety of sizes and widths

- No cracking or crumbling

- Trims cleanly

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Product Insatallation

Surface Preparation: All surfaces to be sealed should be free of dust, dirt, oil, and moisture beforeapplying tape.

Working Conditions: Apply in normal dry working conditions above 40°F (4°C).

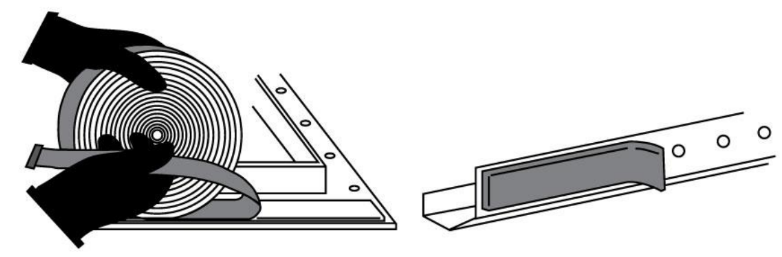

Application: Apply directly from roll onto surface to be sealed. Cut to length with scissors

Product Installation Diagram

Properties

- Color (Properties)

- Typical Properties

Value Units Test Method / Conditions Specific Gravity 15.5 - 15.9 lb./gal ASTM D 792 Low Temperature Flexibility No loss of adhesion or cracking - ASTM C 765 Weight Loss after Heat Aging 0.35 - ASTM C 771 Oil Migration/Plasticizer Bleed-Out No stain - ASTM C 772 Softness Penetration 9.1 - 9.7 mm ASTM C 782 Tensile Adhesive Strength (MOF: Cohesive) 27.5 - 32.7 lb. force ASTM C 907 Yield Strength (lb. force) 7.5 - 8.3 - ASTM C 908

Packaging & Availability

- Packaging Type

- Regional Availability