Enhanced TDS

Identification & Functionality

- Backing Material Type

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Advantages

MH-19 makes construction jobs move smoothly and quickly.

- Superior adhesion

- Stronger than putty tapes

- Easily trimmed with blunt tool

- Awled quickly and cleanly

- Provides watertight seal

- Easy application

- Excellent adhesion to sidewalls

- No discoloration

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Product Insatallation

Surface Preparation: All surfaces to be sealed should be free of dust, dirt, oil, moisture, grease, etc. before applying tape.

Working Conditions: Apply in normal dry working conditions.

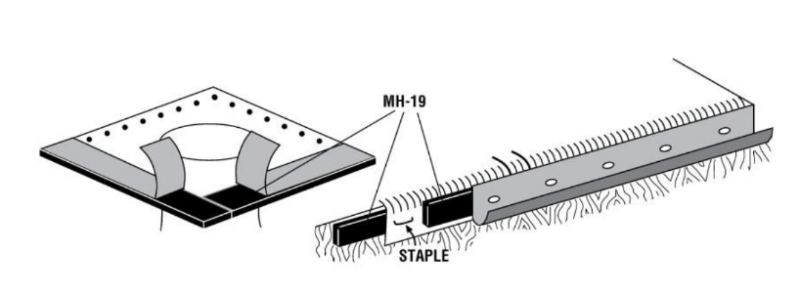

Application: Apply directly from roll or cut to size with knife or scissors. Press MH-19 firmly into place with hand. Intimate contact must be made between tape and subsurface to assure a watertight seal. Gently peel off siliconerelease paper. When lapping tape, allow at least 1/4” (6.4 mm) overlap.

Meets AAMA 807.1-85 Requirements

Product Insatallation Diagram

Properties

- Color (Properties)

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Specific Gravity (US) 15.3 - 15.5 lb./gal ASTM D 792 Low Temperature Flexibility No loss of adhesion or cracking - ASTM C 765 Weight Loss after Heat Aging 0.388 - 0.392 - ASTM C 771 Oil Migration/Plasticizer Bleed-Out Slight wetting on top sheet, No bleed. - ASTM C 772 Softness Penetration 9.5 - 9.9 mm ASTM C 782 Tensile Adhesive Strength (MOF, Cohesive) 31.6 - 36.4 lb. force ASTM C 907 Yield Strength (lb. force) 7.8 - 8.2 psi ASTM C 908

Packaging & Availability

- Packaging Type

- Regional Availability