Enhanced TDS

Identification & Functionality

- Backing Material Type

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Equipment Features

- Ready-to-Use Product Features

- Product Advatages

MB-10A offers many qualities that result in a superior seal, greater longevity, and easier application.

- Greater cohesive strength

- Superior adhesive strength

- Withstands extreme roof temperatures

- Superior low temperature compressibility

- Cold flow resistant

- Resistant to UV light

- Seal not affected by normal movement of building

- Wide service temperature range

- Extensive inventory of standard sizes

- Available in custom sizes and lengths

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Product Installllation

Surface Preparation: All surfaces to be sealed should be free of dust, dirt, oil and moisture before applying sealant.

Working Conditions: For best results, apply in dry conditions above 40oF (4oC).

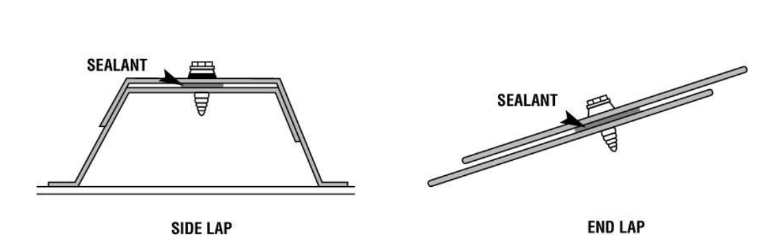

Application: Apply MB-10A to surface directly from roll. Press sealant through the silicone release paper with a smooth, even hand motion. Note: for metal roofing and siding applications, place sealant under the fastener to prevent wind-blown rain from leaking through the fastener holes.

Product Installation Diagram:

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Specific Gravity (US) 15 lb./gal ASTM D 792 Low Temperature Flexibility No loss of adhesion or cracking - ASTM C 765 Weight Loss after Heat Aging (No blisters) 0.13 - ASTM C 771 Oil Migration/Plasticizer Bleed-Out (1st paper) 0.21" - ASTM C 772 Softness Penetration 6.07 - 6.87 mm ASTM C 782 Tensile Adhesive Strength (MOF, Cohesive) 15.25 - 17.65 lb. force ASTM C 907 Yield Strength (lb. force) 10.205 - 11.205 psi ASTM C 908