Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Proper mix ratio - no mistakes

- Single use package - travels well

- Sealed for protection - no contamination

- Color coded to grab & go

- No messy tubes with ill-fitting caps

- Ideal for emergency repairs on tough-to-bond substrates

- Product Attributes

- Bonds: Aluminum, epoxy, glass, wood, and stone

- Easy: Room temperature cure

- Fast: Extra fast setting

- Non-Sag: Non-sag formulation

- Strong: Excellent cohesive strength

- Product Features

Permanently Bond Almost Anything

Epoxy adhesives are higher strength solutions and prevent surfaces from moving. Urethane adhesives retain flexibility and are better suited for structures that contract or expand with temperature. These products offer good chemical resistance, which reduces repeated or nagging repair cycles. GorillaPro epoxies and urethanes can permanently bond almost anything, including engineered thermoplastics, thermosets, nylon, composites, e-coat, and metals.- Strong, rigid bonding

- Excellent resistance to heat and chemicals

- Withstands constant weight or force over time

High-Performance MRO Solutions

Proactive maintenance can help prevent costly unplanned downtime. It’s a challenge keeping up with maintenance activities while keeping teams trained, equipment operating, and driving productivity. With a full complement of maintenance adhesives, repair epoxies, lubricants, and sealants, GorillaPro products can repair and improve the reliability of almost any piece of equipment or machinery.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- Typical Uses

This non-sag, fast-setting epoxy can be used to repair tools, auto parts, electrical and electronic components, furniture and other applications that require a fast-setting adhesive. Ideal for quick, permanent, vertical and overhead repairs. For fixturing, tacking, sealing, gap filling and staking in electrical and industrial applications.

Curing Process:The cure schedule is dependent upon the temperature. The recommended cure schedule will vary with the desired properties.- Application Instruction

Instruction:

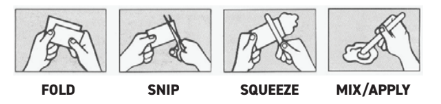

The surface must be clean and dry before application. Remove all chemicals, dirt, wax, and oil. These materials are intended for industrial use only. Fold the DOUBLE/BUBBLE® package along the center seal, snip the end, squeeze out the contents, mix thoroughly and apply.

Avoid contamination with oxidized metals (such as copper, brass, or mild steel), and rust or other metal oxides. The stability of the product is greatly reduced by materials such as strong acids or bases, sulfur compounds, amines, or reducing agents of any type. Surfaces to be bonded must be clean, dry and free from grease, oil, wax, weak oxide films, and other contaminants.

Properties

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Technology/Base Epoxy - - Type of Product Structural Adhesive - - Components Two-Component - - Curing (Secondary Thermal Cure) Room Temperature - - Consistency Non-Sag Liquid - - - Cured Mechanical Properties

Value Units Test Method / Conditions Overlap Shear Strength - Aluminum, Acid Etched (at 25°C, 15 min, 50% RH) 346.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at 25°C, 30 min, 50% RH) 717.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at 25°C, 60 min, 50% RH) 1700.0 psi ASTM D1002 Hardness (Shore D) 83.0 - ASTM D2240 Tensile Strength 7250.0 psi ASTM D638 Elongation at Break 8.5 % ASTM D638 Overlap Shear Strength - Aluminum, Acid Etched (at 25°C, 50% RH) 3712.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at -40°C, 50% RH) 830.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at 82°C, 50% RH) 425.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at 149°C, 50% RH) 174.0 psi ASTM D1002 Overlap Shear Strength - Aluminum, Acid Etched (at 25°C, 24 hours, 50% RH) 3712.0 psi ASTM D1002 T-Peel Strength (at 25°C) 2.7 pli Acid etched Al-Al T-Peel Strength (at -40°C) 1.0 pli Acid etched Al-Al T-Peel Strength (at 82°C) 2.0 pli Acid etched Al-Al Operating Temperature 82.0 °C - - Uncured Properties

Value Units Test Method / Conditions Viscosity - Part A (at 25°C) 465000.0 cPs - Viscosity - Part B (at 25°C) 400000.0 cPs - Viscositv - Mixed (at 25°C) Thixotropic Paste cPs - Specific Gravity - Part A 1.19 - - Specific Gravity - Part B 1.15 - - Specific Gravity - Mix 1.17 - - Volume Mix Ratio 100 - 100 - - Weight Mix Ratio 100 - 94 - - Gel Time (at 25°C) 3 - 5 min - Handling Time 15 - 30 min - Full Cure (at 23°C) 24.0 hours - Alternate Cure (at 25°C) 24.0 hours -

Packaging & Availability

- Packaging Information

The DOUBLE/BUBBLE® package is a handy, dual-pouch, one-shot, job-size package design. It reduces the waste typically associated with the use of larger quantities of two-component adhesives. This unique packaging ensures that DOUBLE/BUBBLE® adhesives are always factory fresh and accurately portioned for optimum adhesive performance.

Storage & Handling

- Shelf Life

- 12 months

- Storage Condition

These materials should be stored in a dry environment within a temperature range of 16 °C to 27 °C (60°F to 80 °F). Extremes of temperature beyond this range may result in crystallization or polymerization of the materials.