Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- New 35ml gel pump dispenser

- No drip - no mess - no waste

- No priming - easy to use

- Product Features

High-Performance MRO Solutions

Gasket Maker:

GorillaPro gasket maker eliminates the need for pre-cut or compression gaskets. Used to fill the voids between metal flanges, it creates a seal that protects the joint against corrosion. GorillaPro gasket maker is resistant to common oils and gasses- Fills all surface imperfections

- Withstands high temperatures and pressures

- Eliminates micromovement and slipping

- Won’t shrink, crack, or relax

- For use on rigid iron, aluminum, and steel flanged surfaces

Pipe Sealant*

In addition to sealing fine threads, GorillaPro pipe sealants can also seal pipe fittings thanks to their ability to withstand most chemicals. These sealants provide a complete seal between threads, offering many advantages over traditional sealing methods like PTFE tape or hemp.- Fills space between threaded parts

- Instant, low-pressure seal

- Prevents fluid and gas leaks

- Withstands most common chemicals

- Ideal for applications such as pipe fittings andhydraulic hoses

- Product Attributes

- Fast: Provides immediate low pressure sealing performance on tapered pipe threads

- Stable: Designed for the locking and sealing of metal pipes and fittings

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- Application Instruction

Surfaces to be bonded should be clean, dry and free of grease. Product should be applied in enough quantity to fill all engaged threads. The product performs best in thin bond gaps. Very large gaps may create gaps that will affect the cure speed and overall strength. Good contact is essential. An adequate bond develops in 15 to 45 minutes and maximum strength is attained per the cure schedule indicated. This product is not recommended for use in pure oxygen environments and/or oxygen-rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials. This product is not designed for plastics, particularly thermoplastics, where stress cracking of the plastic could result. It is recommended to confirm compatibility of the product with all substrates prior to use.

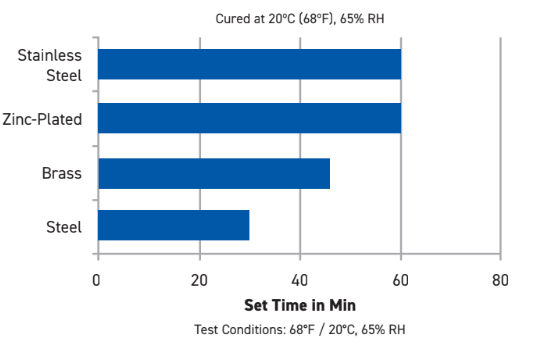

Curing Performance

The rate of cure will depend on environmental conditions and the substrates used. The gap of the bond line will affect set speed. Smaller gaps tend to increase set speed. Activators may be applied to further improve set speed, but may also impair overall adhesive performance.

Properties

- Color (Properties)

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Technology/Base Methacrylate Ester - - Type of Product Pipe Thread Sealant - - Components One Component - - Curing Anaerobic with Secondary Heat Cure - - Consistency Paste - - Viscosity (at 25°C) 280000 - 800000 cPs Brookfield SC4-27 Specific Gravity 1.1 - - - Cured Mechanical Properties

Value Units Test Method / Conditions Locking Strength Low - - Breakaway Torque 25 - 75 in-Ib ASTM D5649 Prevailing Torque 20 - 40 in-lb ASTM D5649 Service Temperature -55 to 205 °C - - Cured Properties

Value Units Test Method / Conditions Full Cure Conditions (at 25°C) 24.0 hours - Cure Appearance Off-White Solid - - - Uncured Properties

Value Units Test Method / Conditions Flash Point min. 93 °C - Gap Fill 0.025 inch - Storage Condition 20.0 °C -

Technical Details & Test Data

- Solvent Resistance

Solvent Example Resistance Alcohol Ethanol, methanol Excellent Ester (aromatic) Ethylacetate Poor Ketone (aromatic) Acetone, benzophenone Poor Aliphatic hydrocarbon (alkanes) Petrol, heptanes, hexane Good Aromatic hydrocarbons Benzyl, toluol, xylol Good Halogenated hydrocarbons Methylenchloride, chloroform, chlorobenzol Poor Weak aqueous acid Nitrite, muriatic acid, sulfuric acid, phosphoric acid Excellent (Poor if concentrated)

Weak aqueous base Sodium hydroxide solution, caustic potash Excellent (Poor if concentrated)

- Test Data

Set Time On Various Substrates

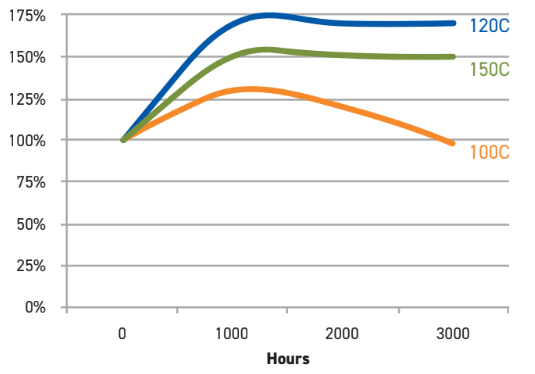

Heating Aging

Aged at Temperature Indicated & Tested at 22°C

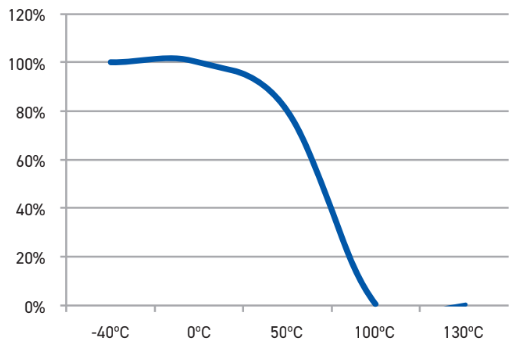

Hot Strength

%RT Strength, Tested at Temperature

Storage & Handling

- Shelf Life

- 12 months

- Storage Condition

Products should be stored unopened in a cool, dry place out of direct sunlight. Products may be refrigerated for improved shelf life, but should be brought back to room temperature before use.