Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Available in slip fit or press fit formulas

- Best choices for non-threaded, cylindrical applications

- Fills inner space between components

- Cures into a hard thermoset plastic that resists loosening

- Color coded for grab-and-go

- Better load transmission and performance

- Product Features

Reliable Retaining Compounds

Retaining compounds durably and reliably retain bearings, shafts, studs, and flanges. In general, the need to dismantle these joints is not required, and GorillaPro retaining compounds are designed for high strength to meet this requirement. They achieve uniform stress distribution throughout the joint, making it possible to withstand dynamic and static loads with equal ease.- Retaining compounds can fill small gaps within twomated assemblies which allows for less costly part designs

- Friction corrosion is avoided

- Replaces clamp rings, set screws, and snap rings, reducing annual maintenance spend

High-Performance MRO Solutions

Proactive maintenance can help prevent costly unplanned downtime. It’s a challenge keeping up with maintenance activities while keeping teams trained, equipment operating, and driving productivity. With a full complement of maintenance adhesives, repair epoxies, lubricants, and sealants, GorillaPro retaining compounds can repair and improve the reliability of almost any piece of equipment or machinery.- Product Attributes

- Fast Flow: Lower viscosity works best for augmenting press-fit applications

- Press Fit: Great for bushing and bearing mount housings

- Cost Savings: Replaces clamp rings, set screws, and snap rings

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Cure Method

- Application Instruction

Surfaces to be bonded should be clean, dry and free of grease. Product should be applied in enough quantity to fill all engaged threads or gap. The product performs best in thin bond gaps. Very large gaps may create voids that will affect the cure speed and overall strength. Good contact is essential. It is recommended to confirm compatibility of the product with all substrates prior to use. This product is not recommended for use with strong oxidizing materials. Where aqueous washing systems are used to clean the surfaces before bonding, these aqueous washes can affect the cure and performance of the adhesive. This product is not normally recommended for use on plastics, users must check compatibility of the product with such substrates.

Curing Performance

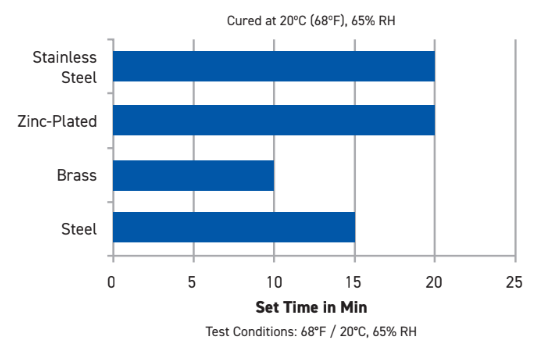

The rate of cure will depend on environmental conditions and the substrates used. The gap of the bond line will affect set speed. Smaller gaps tend to increase set speed. Activators may be applied to further improve set speed, but may also impair overall adhesive performance.

Properties

- Color (Properties)

- Physical Form

- Physical Properties

Value Units Test Method / Conditions Technology/Base Urethane Methacrylate - - Type of Product Adhesive and Sealant - - Components One Component - - Curing Anaerobic with Secondary Heat Cure - - Consistency Wicking Liquid - - Viscosity (at 25°C) 100 - 200 cPs Brookfield SC4-27 Specific Gravity 1.1 - - - Cured Mechanical Properties

Value Units Test Method / Conditions Locking Strength High - - Pin/Collar Shear Strength min. 2500 psi ASTM D4562 Service Temperature -55. to 150 °C - - Cured Properties

Value Units Test Method / Conditions Full Cure Conditions (at 25°C) 24.0 hours - Cure Appearance Green Solid - - - Uncured Properties

Value Units Test Method / Conditions Flash Point min. 93 °C - Gap Fill 0.005 inch - Storage Condition 20.0 °C -

Technical Details & Test Data

- Test Data

Set Time On Various Substrates

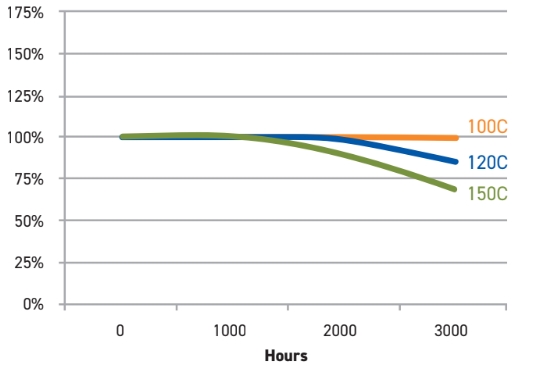

Heating Aging

Aged at Temperature Indicated & Tested at 22°C

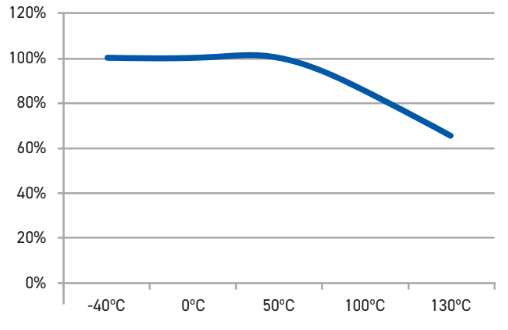

Hot Strength

%RT Strength, Tested at Temperature

- Solvent Resistance

Solvent Example Resistance Alcohol Ethanol, methanol Excellent Ester (aromatic) Ethylacetate Poor Ketone (aromatic) Acetone, benzophenone Poor Aliphatic hydrocarbon (alkanes) Petrol, heptanes, hexane Good Aromatic hydrocarbons Benzyl, toluol, xylol Good Halogenated hydrocarbons Methylenchloride, chloroform, chlorobenzol Poor Weak aqueous acid Nitrite, muriatic acid, sulfuric acid, phosphoric acid Excellent (Poor if concentrated)

Weak aqueous base Sodium hydroxide solution, caustic potash Excellent (Poor if concentrated)

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 months

- Storage Condition

Products should be stored unopened in a cool, dry place out of direct sunlight. Products may be refrigerated for improved shelf life, but should be brought back to room temperature before use.