Enhanced TDS

Identification & Functionality

- Backing Material Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Advantages

PEB-360 offers many qualities that result in a superior seal, greater longevity, and easier application.

- Greater cohesive strength

- Superior adhesive strength

- Withstands extreme roof temperatures

- Superior low temperature compressibility

- Cold flow resistant

- Resistant to UV light

- Seal not affected by normal movement of building

- Wide service temperature range

- Extensive inventory of standard sizes

- Available in custom sizes and lengths

- Key Benefits

- Sealing Power: Creates a locked-out barrier against water, air, and moisture. Say goodbye to leaks and corrosion at the joints of your metal structures.

- Superior Adhesion: Provides robust adhesion strength to a varlety of metal surfaces, ensuring a secure and long-lasting bond.

- All-Weather Reliability: Built to withstand the harshest weather conditions, our Butyl Tape maintains its flexbility and sealing properties in extreme temperatures, high and low.

- Low VOC: Free from harmful chemicals.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Limitations

- Do not apply to damp, frosty or contaminated surfaces.

- Confirm adhesion with intended substrates prior to application

- Not for structural bonding. Requires mechanical fastening or stabilized joints to prevent substrate movement.

- Application

Surface preparation: All surfaces to be sealed should be free of dust, dirt, oil and moisture before applying sealant.

Working conditions: For best results, apply in dry conditions above 40ºF.

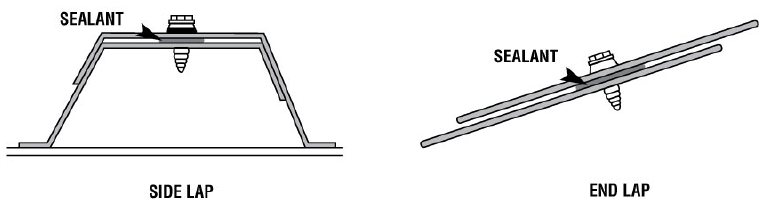

Application: Apply PEB-360 to surface directly from roll. Press sealant through the silicone release paper with a smooth, even hand motion.Note: for metal roofing and siding applications, place sealant under the fastener to prevent wind-blown rain from leaking through the fastener holes.

Product Installllation Diagram:

Properties

- Color (Properties)

- Typical Properties

Value Units Test Method / Conditions Solids Content 0.99 % ASTM C771 VOC Content 0 % ASTM D3960 Softness (Penentration) 9.7 mm ASTM C782 Oil Migration Slight wetting on top sheet. No bleed - ASTM C772 Yield Strength 8.5 psi ASTM C908 Specific Gravity 1.71 - ASTM D792 Pounds/Gal 14.24 - ASTM D792 Cone Penetration Hardness 83.0 dmm ASTM D217 Hardness 20.5 Shore A ASTM C661 Tensile Strength (10”/minute) 5.1 psi ASTM D412 Elongation (10”/minute) 458.0 % ASTM D412 T-Peel (Failure mode, 2”/minute) 1.34 pli ASTM C906 Yield Strength (Failure mode, 1”/minute) 8.5c psi ASTM C908 Low Temp Flex (at -20°F, 1” mandrel) Pass (No cracking, No adhesion loss) ASTM C765 Weight Loss (1 week, at 100°C) 0.02 % ASTM C771 - Application Properties

Value Units Test Method / Conditions Service Temperature -40 to 190 °F ASTM C765 - Flame Characteristics

Value Units Test Method / Conditions Flame Spread ¹ 0.0 - ASTM E84 Smoke Developed ¹ 0.0 - ASTM E84 - Note

¹ - Tested as applied in two 5/8 in. wide strips spaced 8 in. on center covering 7 percent of the exposed test sample area.

Packaging & Availability

- Packaging Type

- Standard Size

3/8" x 3/32" x 50ft L Rolls

Other sizes available on special order

Storage & Handling

- Shelf Life

- 24 Months

- Storage Condition

Store between 20°F - 90°F