Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- ElastiSeal™ Sealant Features

- Excellent adhesion - adheres to a variety of surfaces with primer needed

- Permanently flexible

- Non-stringing formula is easy to apply

- Non-staining formula does not discolor surfaces

Applications & Uses

- Markets

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Recommended Applications

- ElastiSeal™ Sealant is an excellent choice for exterior sealing applications and is compatible with an array of substrates such as glass, metals, concrete, wood, masonry, some plastics and insulation including PIR, PUR and cellular glass and foil, polymeric and kraft insulation facings and jacketing.

- ElastiSeal™ Sealant can also be used for flashing projections, terminations and laps in metal jacketing where a complete moisture and vapor seal is required.

- Limitations

- Store and apply between 40°F and 100°F.

- Always test plastic materials for compatibility when using a solvent-based product.

- Make certain this product is completely dry and the area is free from solvent odor if food is involved.

- Preparation and Application Information

Material Preparation

- Do not thin. Apply only to clean, dry, oil-free surfaces. Keep container closed when not in use.

Application

Flashing Sealant:

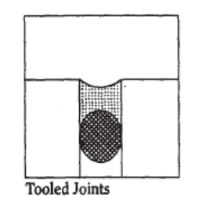

- On stable or secured joints up to 3/16” (4.8 mm) width that experience up to 7.5% joint movement, a bead of sealant may be applied in the joint to fill and seal the gap. For deep joints, insert a backer at a depth equal to the width of the joint.

- Where the joint may experience greater than 7.5% movement or where depth of the joint does not allow for backing or adequate adhesion to the sides of the joint, the sealant shall be applied to bridge the gap by applying/flashing over the adjoining surfaces a minimum of 2” (50 mm) in all directions. Apply a tack coat at 1/16” (1.6 mm) wet film. Embed reinforcing membrane (Mast-A-Fab® or 10x10 glass mesh) into compound. Apply a finish coat at 1/16” (1.6 mm) wet film thickness. Total film thickness to be 1/8” (3.2 mm) wet, giving a 100 mil (2.5 mm) dry film. Allow sealant to dry a minimum of 8 hours before applying finish mastic over its surface. When flashing, do not trowel out to feather edge, but maintain a minimum of 1/8 in. (3.2 mm) wet film thickness throughout entire area of use. For best application, the material temperature should be 60°F or higher.

Metal Jacketing:

- Apply a 0.25” (6 mm) bead of sealant underneath the lap. Jacketing shall be firmly embedded and pulled up tight and banded in place. All overflow of sealant shall be removed with solvents.

Clean Up

- Use solvent such as VM&P Naptha or Mineral Spirits for cleaning tools and equipment.

Properties

- Color (Properties)

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Average Weight / U.S. Gallon 10.8 lbs. ASTM D1475 Average Non-Volatile (by Weight) 80 % ASTM C681 Shrinkage max. 20 % ASTM D2453 Water Vapor Permeance (at 100°F, 90% RH, 0.078 in dry film thickness) 0.02 perms ASTM F1249 Water Vapor Permeance (at 73°F, 50% RH, 0.078 in dry film thickness) 0.04 perms ASTM F1249 Flash Point 105 °F ASTM D56 VOC Content (Less Water) 250 g/l - Drying Time (Through) 72 hours ASTM D2377 Drying Time (Full) 21 days ASTM D2377 Coverage Range (1/8 in. bead) 125 linear ft./10.5 fluid oz. tube Coverage Range (1/4 in. bead) 30 linear ft./10.5 fluid oz. tube Drying Time (Touch) 2 hours ASTM D2377 - Application Properties

Value Units Test Method / Conditions Service Temperature Limits (at sealant surface) -40 to 121 °C - Flame Characteristics

Value Units Test Method / Conditions Flame Spread ¹ 0 ASTM E84 Smoke Developed ¹ 0 - Note

¹ - Tested in two 1/8” beads spaced 8” on center applied to 1/4 inch inorganic reinforced cement board. The flame spread may vary at different product thicknesses and/or when applied over other surfaces.

Regulatory & Compliance

- Chemical Inventories

- Quality Standards

- Applicable Standards

Federal Specifications:

- TT-S-001657 Type I - Butyl Rubber, Solvent Release Sealing Compound for Buildings

- TT-C-1796A - Caulking Compound for Metal and Wood Seam

Packaging & Availability

- Regional Availability