Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Application

Surface Preparation

- Surfaces must be clean and free from dust, fatty substances and release agents.

- For optimumadhesion, the surface tension of the substrates to be bonded should be more than 38 dynes/cm.

- Recommended surface preparation for optimal adhesion is as follows:

- PC, ABS, Glass: IPA wipe

- Nylon: Plasma treatment

Application Instructions

- Place adhesive film between substrates.

- Optional: Prelamination at bondline temperature (BLT) of 60°C for 10 to 30 seconds and pressure of 0.20 to 0.50 MPa.

- Final bonding: Bondline temperature (BLT) of 90 to 130°C for 25 to 90 seconds at pressure of 0.20 to 0.50 MPa

- The glued materials can be further processed immediately after bonding and cooling down (handling, trimming, cutting, etc.)

Properties

- Color (Properties)

- Typical Properties

Value Units Test Method / Conditions Specific Gravity 1.16 - - Solid Content 100.0 % - Melt Flow Rate 4 - 13 dg/min DIN 53920 Standard Film Thickness 25, 50 μm -

Technical Details & Test Data

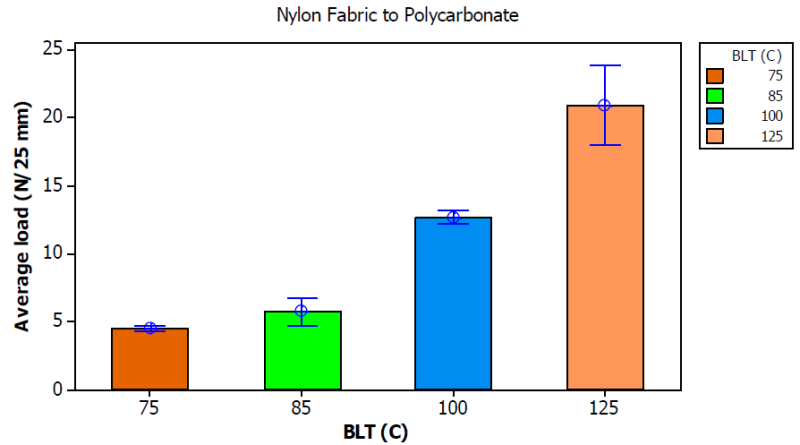

- Flexel™ TPF4050 Typical Peel Strength (Effect of BLT)

- Pressed at BLT listed for 25 seconds at 0.22 MPa

- Pulled at crosshead speed of 300 mm/min

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months

- Storage Conditions

- Flexel™ TPF4050 should be stored in a cool, dry place.

- It should be stored in between 0 and 40°C.