Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Surface Application

Surfaces must be clean and free from dust, fatty substances and release agents. For optimum adhesion, the surface tension of the substrates to be bonded should be more than 38 dynes/cm.

Recommended surface preparation for optimal adhesion is as follows:

- PC, ABS, Glass: IPA wipe

- Nylon: Plasma treatment

- Application Instructions

- Place adhesive film between substrates

- Cure Activation Conditions

- Temperature: 75°C - 110°C

- Activation Time: 30s - 90s at temperature

- Pressure: 10 - 25 N/cm²

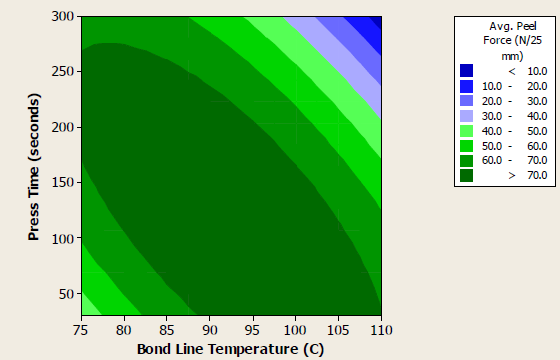

- We recommend uniform pressure distribution for optimal bonding. Use the contour plot on the right as a guild to determine the optimum bonding conditions for your process.

- The glued materials can be further processed immediately after bonding and cooling down (handling, trimming, cutting, etc.)

- Optional step: EM9002 adhesive film may be pretacked to a substrate prior to processing. To pre-tack EM9002 to a material, use the processing guide lines below:

- Bond Line Temperature: 45 - 50°C

- Pressure: 5 - 20 N/cm²

Note: The chart above shows typical peel strength (N/25 mm width) when bonding polycarbonate coupons to nylon fabric with Flexel™ EM9002-50. This is 180° degree peel data, pulled at 300 mm/min. After the parts were bonded, they were allowed to condition at 23°C and 50% relative humidity for about 24 hours.

Properties

Technical Details & Test Data

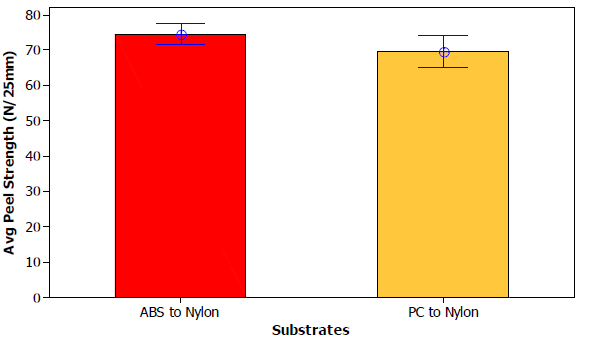

- Typical Peel Strength

95% CI for the Mean

Note: Peeled at crosshead speed of 300 mm/min. Samples were pressed for 60 seconds at bond line temperature of 90°C and pressure of 22N/cm². Peel samples were conditioned for 24 hours at 23°C and 50% relative humidity before testing.

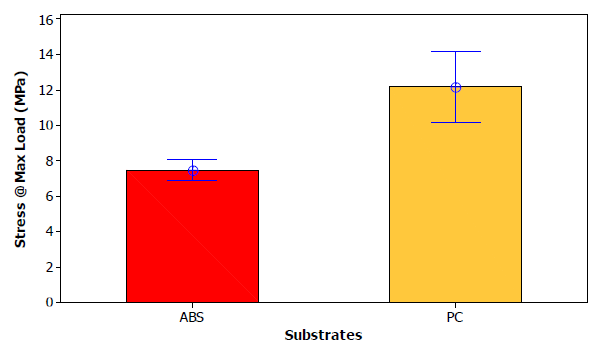

- Typical Shear Strength

95% CI for the Mean

Note: Pulled at crosshead speed of 30 mm/min. Shear area is 25 mm x 12 mm. Samples were pressed for 60 seconds at bond line temperature of 90°C and pressure of 22N/cm². Shear samples were conditioned for 24 hours at 23°C and 50% relative humidity before testing.

Packaging & Availability

- Regional Availability

- Film Thickness

EM9002 is available is a range of thickness, which is noted by the product name extension:

- EM9002-25 = 25 μm film thickness

- EM9002-50 = 50 μm film thickness

- EM9002-75 = 75 μm film thickness

- EM9002-100 = 100μm film thickness

Storage & Handling

- Shelf Life

- 9 Months

- Storage Condition

EM9002 should be stored in a cool, dry place. Store below 30°C.