Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Features

- Excellent adhesion - adheres to a variety of sur- faces without primer

- Permanently flexible

- Non-stringing formula is easy to apply

- Non-staining formula does not discolor surfaces

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Basic Use

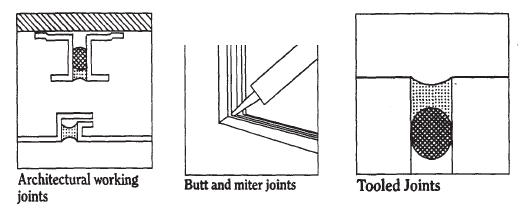

ElastiSeal® B-100 is used in architectural working joints, butt and miter joints, and tooled joints.

- Applicable Standards

- AAMA 808.3-05 Exterior Perimeter Sealing

- USDA Certified

- ASTM C 1311-Solvent Release Sealants in Building Construction, max joint movement of ± 7.5%

- Federal Specifications

- TT-S-001657 Type I - Butyl Rubber, Solvent Release Sealing Compound for Buildings

- TT-C-1796A - Caulking Compound for Metal and Wood Seam

- Limitations

- All surfaces to be sealed or bonded must be clean and dry and free from contaminants. Primer may be required for certain surfaces.

- ElastiSeal® B-100 is not recommended for use in window glazing applications or hidden joint details, which require a non-skinning, non-hardening sealant.

- Application Instructions

- All Surfaces must be clean and dry.

- Apply with standard caulking gun.

- Cut nozzle to desired bead size. Puncture inner seal

- Apply at a 45 angle using constant pressure.

- Use at room temperature for ease of gunning.

- Tool or join surfaces for sealing before material skins.

- Support tooled or joined surfaces for 8 hours minimum.

- Use VM&P Naphtha or Mineral Spirits to remove excess material before skin forms.

- Clean Up

With VM&P Naphtha or Mineral Spirits

Properties

- Color (Properties)

- Typical Properties

Value Units Test Method / Conditions Specific Gravity 1.3 - ASTM D1475 Press-Flow Viscosity (at 40 psi) max. 3 seconds/gram ASTM D2452 (modified) Sag or Flow max. 0.15 inch ASTM D2202 Tack Free Time 2 Hours ASTM D2377 Solids Content min. 80 % ASTM C681 VOC Content 250 g/L ASTM D3960 Shrinkage max. 20 % ASTM D2453 Method of Cure Solvent Release. Cured in 21 days. - ASTM D2377 Stain Index max. #3 - ASTM D2203 Flash Point 40 °C ASTM D56 - Application Properties

Value Units Test Method / Conditions Service Temperature -29 to 93 °C ASTM D3359 Application Temperature 4 - 49 °C ASTM C603 Storage 18 - 48 °C ASTM D1337 - Note

The foregoing information is published as general information only. The listed properties and performance characteristics are approximate values and are not to be interpreted as manufacturing specifications.

Packaging & Availability

- Packaging Type

- Regional Availability

- Packaging Information

- 11 fluid ounce cartridge

- Five gallon Pail

- 55 gallon Drum

Storage & Handling

- Shelf Life

- 1 year