Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- General Information about Anaerobic Adhesives

Anaerobic adhesives and sealants cure by means of metal contact and/or due to the absence of air. Due to these facts they are only suitable for bonding and sealing metals. Therefore, as such they are not traditional adhesives as commonly known, but are specifically good for the bonding of metal cylindrical parts where torsion-load and shearing-load play an important part. Furthermore, anaerobics are excellent sealants for threads and flanges. Anaerobis are solvent free, one component adhesives. There are active metals (construction steel, tool steel, free cutting steel, brass, copper) and inactive metals (high alloyed or stainless steel, aluminum, electroplated surfaces, cast iron). While products used on active metals cure very fast, the same products need longer times to cure when used on inactive metals. But this does not influence the intended strength.

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Application Details

Clean Surface

The surface condition of the mating parts has an enormous influence on the success of a bond. To achieve good bonding success the mating parts should be clean. A certain amount of e.g. oil can be tolerated.

Additional Program

In order to support certain applications Cyberbond offers perfectly balanced additional products such as: - Activator: in order to accelerate the curing of adhesives (Standard: CB 9191) - Cleaner: in order to clean surfaces professionally (Standard: CB 9999)

Properties

- Physical Properties

Value Units Test Method / Conditions Density (at 20°C, monomer) 1.06 g/cm³ - Gap Filling Capacity (Monomer) 0.06 - 0.18 mm - Viscosity (Cone/plate, at 20°C at 160 s⁻¹) 2.500 - 3.500 mPa.s - Shear Strength on Steel (polymer) 24 - 44 N/mm² - Maximum Thread (Monomer) M 20 - - Setting Time (M10 brass bolt/nut) 10 - 30 sec - Full Cure Time (Polymer) 24 hours Temperature Range (Polymer) -50 - 180 °C -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Technical Information

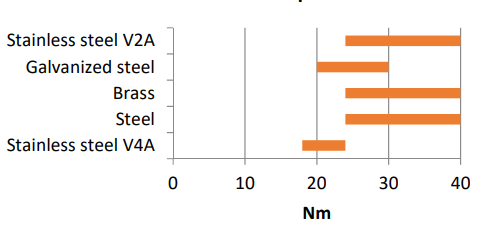

Adhesive Strength Substrate

Nm Adhesive strength (Stainless steel V2A)

24 to 40 Adhesive strength (Galvanized steel)

20 to 30 Adhesive strength (Brass)

24 to 40 Adhesive strength (Steel)

24 to 40 Adhesive strength (Stainless steel V4A )

18 to 24 Breakloose Torque

Solvent Resistance

Solvent Example Resistance alcohols ethanol, methanol, isopropyl alcohol + esters ethylacetate, benzoic benzyl ester, + other liquids water, freon, diesel oil + other liquids ammonium hydroxide, bromine, hydrobromic acid, lithium hydroxid, perchloric acid, potassium hydroxide - gasses acetylene, argon, butane, ethane,nitrogen + gasses ammonia, freon gas, oxygen (pure and /or oxygen rich systems), chlorine - Measurement of Viscosity

Viscosity describes the flow-ability of a liquid. Cyberbond measures the viscosity of the products by means of the cone/plate method: the liquid is applied on a panel and a defined cone presses the liquid together and rotates. You differentiate between a Newtonian and a thixotropic liquid. In terms of a Newtonian liquid you will get a relative constant viscosity graph in dependence of the rotary speed of the cone. In terms of thixotropic liquids the product becomes more liquid (down to its base viscosity) the faster the cone rotates. The viscosity is measured in mPa*s

Safety & Health

- Safety Information

- Keep the workplace clean and use in well ventilated areas only.

- Installll suitable exhaust system at the workplace.

- Wear suitable safety glasses and gloves.

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months (at 20°C in unopened bottles, Monomer)

- Storage Conditions

Store products in a cold and dark place. Optimal storage temperature range is between 8 °C - 21 °C.