Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

- Base Compound

Alkoxyester

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

Cyanoacrylates are fast setting, one component and solvent free adhesives. They are based on esters of cyanoacetic acid. To get to a finished product, mainly thickeners, respectively film forming agents (polymer methacrylics and acrylics) and stabilizers are added. The polymerization is initiated by present humidity. Best results are given between 40 to 70 % relative humidity.

Cyberbond standard grades are as follows:

- Powerdrop series (stabilized ethyl ester)

- Elastomer and plastic series (ethyl ester)

- Neomer Series (surface insensitive ethyl ester)

- xtraflex series (rubber toughened ethyl ester)

- metal series (ethyl ester)

- low odor series (alkoxy ester)

- medical series (butyl- and octyl ester)

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Solvent Resistance

Solvent Example Resistance Alcohol Ethanol, Methanol Very Good Ester (aliphatic) Ethyl Acetate (Acetic Acid Ethyl Ester) Very Bad Ketones Acetone, Benzophenone Very Bad Aliphatic hydrocarbons (alkanes) Petrol, Heptane, Hexane Good Aromatic hydrocarbons Benzene, Toluene, Xylene Good Halogenated hydrocarbons Methylene Chloride, Chloroform, Chlorobenzene Very Bad Weak acqueous acids Diluted Nitric- , Muriatic-, Sulfuric- , Phosphoric Acid Very Good Concentrated acid Nitric Acid, Muriatic Acid, Sulfuric Acid, Phosphoric Acid Very Bad Weak acqueous bases Diluted Sodium Hydroxide -, Caustic Potash Solution Very Good Concentrated bases Sodium Hydroxide -, Caustic Potash Solution Very Bad Water Good Iso-propanol Very Good Acetone Very Bad Mineral oil Good - Clean Surface

The surface condition of the mating parts has an enormous influence on the success of a bond. To achieve good bonding success the mating parts should be clean.

- LINOP Equipment

Cyberbond offers by means of the LINOP Equipment range suitable dosing and LED based curing devices. We also refer to suitable dosing tips which help an economical use of the adhesives (also if used manually).

Properties

- Appearance

- Colorless, transparent (Monomer), Transparent (Polymer)

- Physical Properties

Value Units Test Method / Conditions Service Temperature Range -30 - 70 °C - Setting Time (Metal - Steel) 10 - 55 sec - Setting Time (EPDM) 3 - 30 sec - Setting Time (Plastic - ABS) 20 - 30 sec - - Typical Properties

Value Units Test Method / Conditions Viscosity (at 20°C, 160 rpm) 800 - 1500 mPa.s Cone-plate - Uncured Properties

Value Units Test Method / Conditions Density (at 20°C) 1.1 g/cm³ - Flash Point min. 80 °C -

Regulatory & Compliance

- Specification

- ISO 10993-5: Test for in vitro cytotoxicity (biocompatibility).

- RoHS conform.

Technical Details & Test Data

- Technical Details

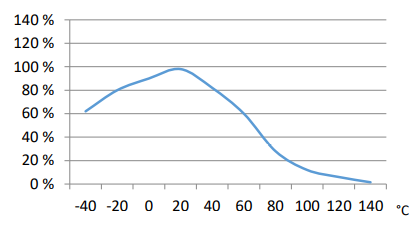

Hot Strength on Steel

% of RT strength, tested at temperature.

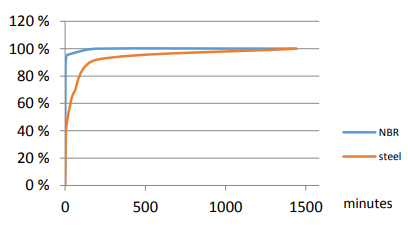

Time Until Full Cure

% of RT strength

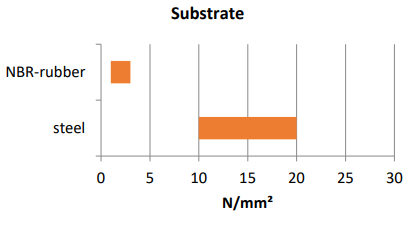

Strength of Cured Adhesive

Substrate N/mm2 NBR-rubber ▲ 1 to 3 steel 10 to 2 ▲ material failure

- Measurement of Viscosities

Viscosity describes the flow-ability of a liquid. Cyberbond measures the viscosity of the products by means of the cone/plate method: the liquid is applied on a panel and a defined cone presses the liquid together and rotates. You differentiate between a Newtonian and a thixotropic liquid. In terms of a Newtonian liquid you will get a relative constant viscosity graph in dependence of the rotary speed of the cone. In terms of thixotropic liquids the product becomes more liquid (down to its base viscosity) the faster the cone rotates. The viscosity is measured in mPa*s (milli Pascal x second) [SI system] or in cP (centipoise) [CGS- system]; 1 mPa*s = 1 cP. In order to allow products comparison all adhesives are measured at the same rotation speeds.

- Newtonian liquids at 160 upm

- Thixotropic liquids at 0,5 upm and at 160 upm

Temperature always is at 20 °C / 68 °F, if not mentioned to be different.

Safety & Health

- Potential Danger of Cyanoacrylates

You should care for the following:

- Use in well ventilated areas only

- Installll suitable exhaust systems in the workshop

- Apply material economically and use a dosing system where appropriate

- Allow a consistent relative humidity of 50 to 65 %; with regards to lower figures the polymerization will be delayed and monomer adhesive fume will appear

- If necessary: wear suitable, non-sucking gloves (Eg. No cotton)

- Keep adhesive out of reach of children

The data mentioned in this TDS, particularly the recommendations and use of products are based on our recent knowledge and experience. Due to the fact of having so many different materials involved and conditions of applications which are out of our influence, we strongly recommend to do sufficient tests in order to guarantee that Cyberbond products are suitable for the intended process and applications. Except for wilful acts any liability based on such recommendations or any verbal advice is hereby expressly excluded.

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 12 Months (at 20°C, unopened)

- Storage Conditions

Store products in a cold and dark place. Before use allow to reach ambident temperature.