Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Characteristics

- This product demonstrates film formation with good blockresistance and heat seal-ability

- Free of fluorine and maintains a grease resistant coating withprintability

- Product is formulated to be coater ready for Flexo/Gravure andMayer Rod processes

- Key Benefits

- Heat-sealable technology

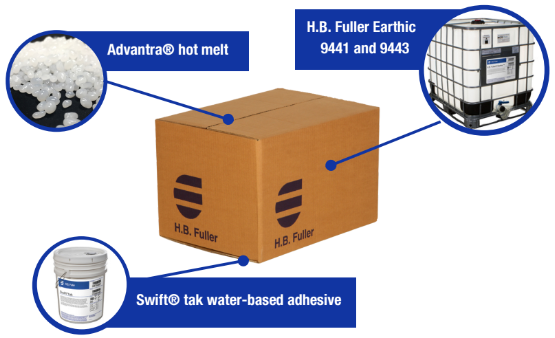

H.B. Fuller Earthic 9443 is a polyolefin-free water-based barrier coating innovative solution for fiber-based packaging used to ship goods bought online and shipped directly to consumers. It is heat sealable to itself and to paper, and can be applied using mayer rod, gravure/anilox roller, jet blade, curtain or knife coating at paper mill or packaging maker.

- Protect your products

H.B. Fuller Earthic 9443 was formulated by our expert engineers to provide moisture-resistant packaging. Additionally, it can withstand high heat e-commerce packaging shipping environments and protects contents inside e-commerce packaging with as little excess packaging as possible.

- Recyclability

Water-based barrier coatings are an alternative to polyethylene (PE) coatings. PE coatings may prevent packages from being recycled at standard recycling centers. Packages coated with H.B. Fuller Earthic 9443 achieve improved fiber yield compared to PE coatings during the repulping process. This results in the potential for higher volume of high quality fibers to be added to the recycling stream.

- Polyethylene free, wax free, and fluorochemical free

- Passes Fiber Box Association Part I and Part II Repulpability and Recyclability Voluntary Test Method

- Compliant with BfRxxxvi direct food contact and 21CFR 176.170 for food types IV-A, V, and VII under conditions of use E through G and with food type VIII and IX under all conditions of use

- Heat sealable to itself and paper up to 80°C

- Low coat weight with superior moisture resistance

H.B. Fuller Earthic 9443 offer strong moisture and grease resistance that allows paper coaters and packaging makers to achieve a lower coat weight than competitor water-based coatings. It has an easy-to-apply uniform consistent coat to produce an average total dried coat weight of 5 gsm with a cobb rating <10 and Kit rating >10 with flexo application. This allows for reduced coating and paper waste, reduced product claims and improved quality control.

Applications & Uses

- Application Area

- Application Method

- Compatible Substrates & Surfaces

Properties

- Typical Properties

Value Units Test Method / Conditions Solids 46 - 48 % - pH 8 - 9 - - Glass Transition Temperature (DSC Mid-Point) 9.0 °C - Viscosity (Brookfield RVT, at 24 - 26°C) 125 - 350 cPs - - Performance Properties

Value Units Test Method / Conditions Cobb (30 minutes) 9.0 g/m² - Surface Energy 36.0 dyne - Tappi Kit Grease Rating 11.0 - - Heat Seal (200°F, internal temp to paper) Fibre pull - - Block (at 60°C, 200 psi, 1 Hour) Slight stick - - - Note

Performance Testing on Kraft Paper at 10gsm coat weight

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Regional Availability

Storage & Handling

- Shelf Life

- 6 months

- Storage Conditions

In original sealed packaging protected from sun, dust, moisture and high temperatures. Clean and dry conditions above +15°C and below +30°C. Do not freeze.